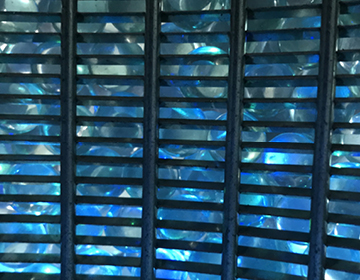

Filter glass beads instead of Filter gravel

Efficient and resource-saving water extraction will be one of the great challenges of the future. In cooperation with universities and industry experts, we have researched methods for the use of glass beads as support and filter material. The results confirm that our SiLibeads® glass beads made of soda-lime glass are superior to mineral sands and gravel in their physical, chemical and hydraulic properties. Since 2007, more than 1500 wells worldwide have been equipped with SiLibeads® glass beads.

Advantages

The following advantages over commercially available filter gravel were found:

SiLibeads® glass beads have almost the ideal shape of a ball with a smooth surface, which significantly reduces the depositing behaviour of incrustations and reduces the regeneration frequency of the well.

Due to their homogeneity, SiLibeads® have a very high breaking strength, which is 10 times higher than filter gravel. Thus filling the well’s annular space with SiLibeads®, no breakage, undersize particles, or formation of siltation particles occur.

SiLibeads® feature a very narrow grain size distribution range and are available in all size distributions. This allows the bead size to be selected according to the soil conditions. This also helps to avoid siltation and reduce incrustations and thus further reduces the need for regeneration. In addition, the filling of the well ring chamber with SiLibeads® prevents the disadvantageous bridge formations.

SiLibeads® soda-lime glass beads are free of impurities and heavy metals and show no toxicological element concentrations in acid-based regeneration agents.