History

Acquisition of the Bioglitter™ business unit from Ronald Britton Ltd and RJA Plastics GmbH

SiLiglam PURE BIO SPARKLE receives OK biodegradable WATER certification by TÜV Austria

Certification: ISO 14001Successful start of the new Type M department at the SiLiglit plant

Installation of a photovoltaic system

Successful certification according to ISO 50001

Successful certification of the development, manufacturing process and distribution of our Cosmetic Glitter range SiLiglit, SiLiglam and SiLiglam PURE according to ISO 15378.

New SiLiglit production site workes operational

Five million Euro Investment in new production site

SiLibeads Filterbeads get certified according to NSF regulations

Successful certification of our products and sales of our glass beads as primary packing material for pharmaceutical products, according to ISO 15378.

Applying GMP principles in the production and control of primary packing materials for medical products is of utmost importance for the safety of patients using medical products and medicines, due to their direct contact with the packing material (contamination risk). Applying GMP principles for pharmaceutical packing materials guarantees that the requirements comply to and fulfil the legal regulations, and those of the pharmaceutical industry for medicines. The certification according to ISO 15378, having been carried out by an independent institute, has confirmed that the acknowledged GMP rules have been adhered to and that Sigmund Lindner GmbH conducts an effective management system. Our customers can rely on that!

Sigmund Lindner GmbH was awarded a certificate by the Chamber of Commerce and Industry Oberfranken (IHK) during the competition “Großer Preis des Mittelstandes” (Main Award for Medium-Sized Enterprises) of the Oskar-Patzelt Foundation.

14th June: Dedication and enthusiasm – 300 runners taking part in the 1st SiLi Run at the occasion of the 155th anniversary of SiLi in Warmensteinach.

Completion of the new building of the glitter production unit and opening of the company canteen.

Foundation of SiLi Technologies for R & D.

Enlargement of production capacities for ceramic beads. Introduction of SiLibeads Type ZS to the market – Beads made of zirconium silicate. Expansion of our site in Warmensteinach and realisation of numerous investments in both production and stock facilities and state-of-the-art plant engineering. The number of employees increases to more than 90 persons.

Introduction of SiLibeads Ceramic Beads Type ZY Premium to the market for use in the pharmaceutics, cosmetics and food industries. Foundation of the joint venture – Jingong Tiantai SiLi Glass Beads Factory – in China.

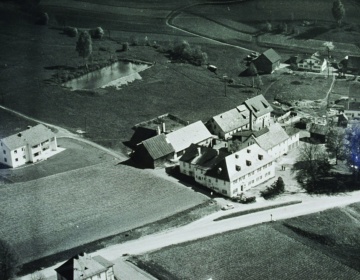

celebrating 150 years of company Sigmund Lindner and opening of new production and stock facilities over an area of 7000 sqm

presentation of the new technical ceramic beads and opening of the clean room for SiLibeads Type P from Type I Glass for the Pharmacy; establishment of Sigmund Lindner Italia

completion of the developing of the technical ceramic beads and start of the series production

establishment of the joint venture Cer-O-Glass in Tennessee/USA; completion of the production hall for technical ceramic beads

establishment of Sigmund Lindner UK; completion and opening of the new administrative building

certification of our quality management according to DIN ISO 9001:1994 and successful start to deliver SiLibeads Type I glass for the pharmaceutical industry and medical engineering

takeover of the company Dragon Werke and movement of the production to Warmensteinach

introduction of an ecologically desirable polishing process for technical glass beads

introduction of the revolving furnace system to produce technical glass beads

creation of a European distribution network for aluminium and polyester glitter

production start of technical grinding media made of glass for pearl mills

demolition of the melting pot for the decorative glass pearls

construction of the first melting pot for glass pearls

building of a production hall for glass diamantine, today called glass glitter

already at that time brisk export of the products to England, South America, India etc.

start of the glass diamantine production

establishment of the company by Sigmund Lindner and start of the manufacturing of decorative coloured glass pearls – iron spindles and melting pots were of help