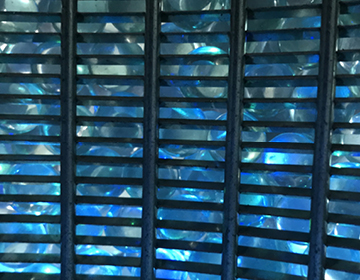

Glass beads have the following advantages in well construction

Glass beads are used in drinking water wells for several reasons, which mainly centre on the following:

Support layer: glass beads can be used as an effective support layer in drinking water wells. Their smooth surface and uniform shape allow for efficient retention of particles from the rock. Compared to traditional sands and gravels, glass beads can provide a better support layer as they are less prone to clogging and allow for a more efficient flow rate.

Durability and maintenance: Glass beads are chemically inert and do not corrode or degrade in water. This makes them a long-lasting option that requires less maintenance than other fillers. Their durability means they need to be replaced less often, saving costs in the long run.

Environmentally friendly: As glass beads are often made from recycled glass, they offer a more environmentally friendly alternative to other filler materials. Their durability and resistance to breakage help to reduce the environmental impact.

Reduction of biofilm and algae growth: The smooth surface of glass beads can impede the growth of biofilm and algae that can form in sands/gravels. This helps to maintain water quality and reduces the need for chemical cleaning agents during regeneration.

Overall, glass beads in drinking water fountains contribute to the efficiency and effectiveness of the drilling brine, improve water quality and are a sustainable, low-maintenance option.

The use of glass beads in drinking water wells not only brings advantages in the support layer itself, but also when regenerating the wells:

Easier regeneration: compared to traditional filling media such as gravel, glass beads allow for easier and more efficient regeneration of the system. Their smooth surface prevents the ingress of impurities, which makes it easier to wash out and clean the beads.

Less tendency to clog: Glass beads are less prone to clogging as they have a lower surface roughness than gravel. This extends the intervals at which the fountain needs to be regenerated, thus reducing maintenance costs and effort.

Longer service life of the well system: Due to their chemical inertness and mechanical stability, glass beads contribute to a longer service life of the entire well system. This leads to fewer replacement cycles and lower long-term costs.

Sustainability: Glass beads can be regenerated and reused multiple times, making them a more sustainable option compared to other fill materials that may need to be replaced more frequently due to easier wear, higher breakage of the material.

Reduced use of chemicals: As glass beads minimise the growth of biofilms and algae, the use of chemicals to clean and disinfect the well water can be reduced. This not only helps to protect the environment, but also reduces operating costs.

To summarise, glass beads not only improve the performance of drinking water wells, but also offer significant advantages in the regeneration of wells. They facilitate maintenance, increase the efficiency of regeneration, extend the service life of the lining system and contribute to more sustainable water treatment.

Do glass beads make it easier to desand or run in the wells?

Glass beads can actually facilitate the so-called “desanding” or “running-in” of wells, which are processes that are carried out when commissioning new wells or after maintenance work on existing wells. Here are some of the benefits that glass beads can offer in this context:

Efficient particle removal: Desanding removes fine sand and sediment particles that may have entered the well during construction or maintenance. Glass beads can help to pass these particles effectively and quickly, as their smooth surface and uniform size allow for efficient particle passage.

Reduced risk of blockages: Compared to other fillers such as sand or gravel, glass beads have significantly better hydraulic behaviour. This is particularly advantageous when running in a well, where there is an increased amount of fine particles.

Improved stability of the support layer: Glass beads can form a stable support layer, which reduces the risk of channel formation (i.e. the formation of low resistance paths in the filter material). A stable support layer is crucial when desanding and retracting a well to ensure an evenly distributed fill.

Durability and low maintenance: As glass beads are chemically inert and do not wear out, they last longer and require less maintenance. This is particularly important in the initial phase of well operation, where frequent maintenance could be problematic.

Overall, glass beads can therefore not only facilitate the desanding and commissioning of wells, but also make them more efficient and cost-effective. They help to improve water quality and optimise commissioning and maintenance processes.