ADDITIVE MANUFACTURING of ceramic components

Additive manufacturing is characterized by several advantages over other manufacturing processes. In addition to tool-free manufacturing and the associated suitability of the process for one-off and small-batch production, it offers the user new freedom in the areas of component design and material selection. In combination with the characteristic properties of ceramic materials such as zirconium oxide, aluminum oxide or even tungsten carbide, the manufacturing process enables us to further optimize the grinding process.

Grinding container concept for use in a centrifuge

-> grinding of solvent-containing suspensions on a laboratory scale

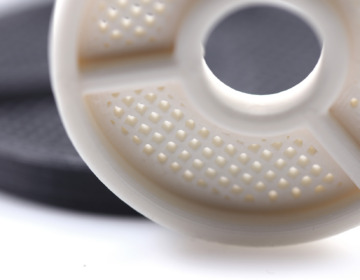

Components with different screen structures made of ceramic materials

-> separation of grinding media from suspensions containing solvents

Extruder screw with improved durability in different design and material variations

-> suspension conveying in agitator ball mill

Advantages of additive manufacturing:

- Tool-less manufacturing

- Extended design freedom

- Single/small batch production

- Multi-material components

Advantage ceramic components:

- Chemical resistance

- Biocompatibility

- Heat resistance

- Thermal shock resistance